Electronics Assembly

Adhesives

Designed to meet today's demands for strength, durability and versatility

Increasing mass production and miniaturization of electronic devices calls for faster, stronger and more precise bonding processes to new substrates. At Bostik, we understand the challenge this brings when it comes to addressing:

- Precise application needs

- Design requirements

- Aesthetic demands

By analyzing the limitations of other assembly adhesive bonding technologies, our experts were able to address them with innovative instant engineering adhesives that propel your manufacturing processes and end-use electronics forward, offering:

- Enhanced worker safety and comfort due to low odor

- Improved final aesthetics due to low blooming

- Increased performance capabilities due to being less brittle than conventional instants

- Heightened application flexibility due to various open and fixture times

FIND OUT WHAT CONSIDERATIONS TO MAKE WHEN NEEDING AN ELECTRONICS ADHESIVE.

Born2Bond® Engineering Adhesives

Today, engineering adhesives are the primary solution for assembling electric vehicles, smartphones, medical and other electronic devices.

Available in a range of advanced formulations, Born2Bond® instant adhesives overcome many of the performance and application limitations of existing solutions. They also facilitate faster, smarter production processes while prioritizing user safety and sustainability.

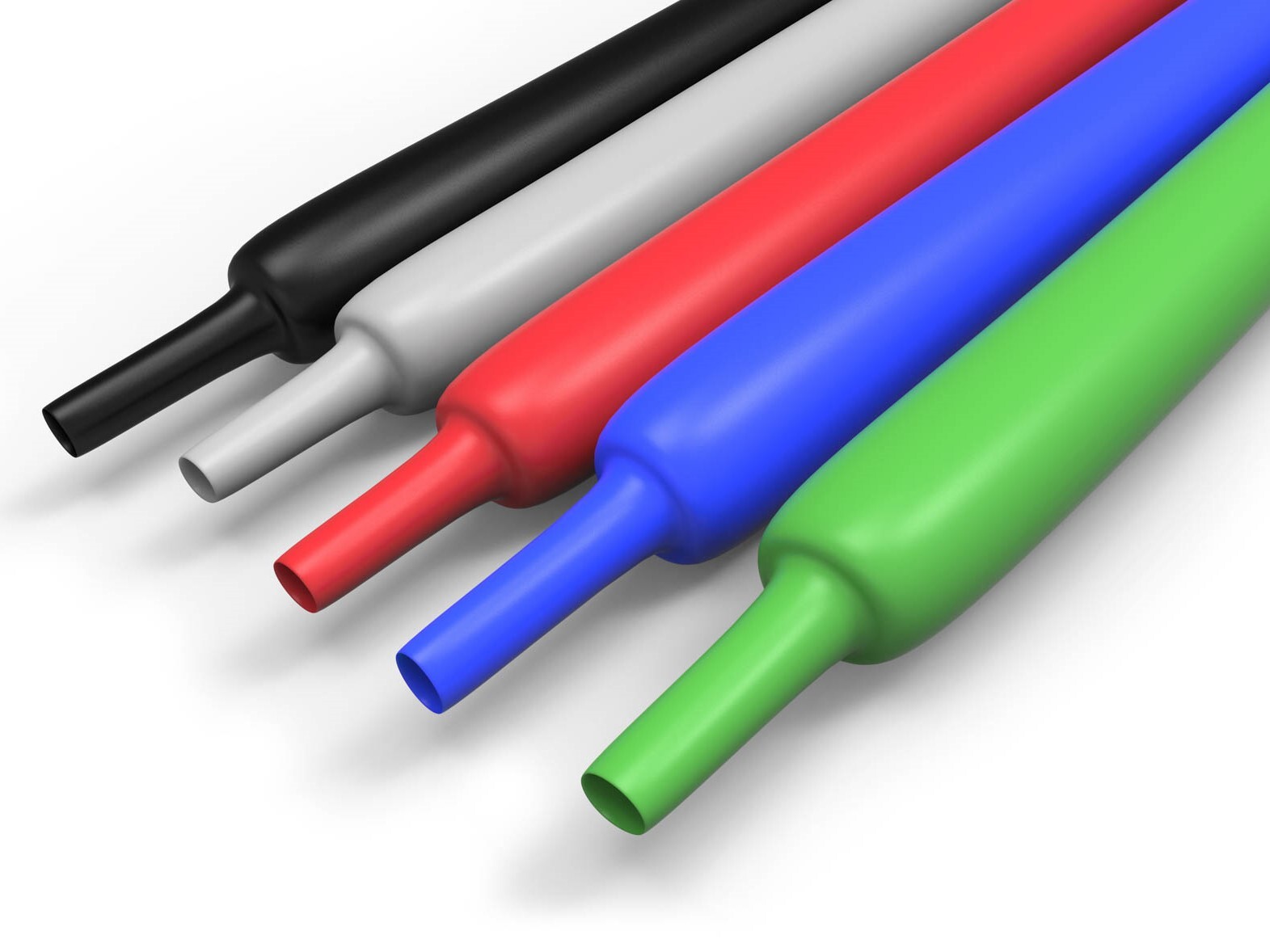

Heat shrinkable tubing (HST)

HST provides quick and easy solutions for cable bundles, electric insulation, sealants, and other types of protection. Used in wide variety of applications, including electronics, automotive, appliance, or underground pipelines, the dual wall addition with inner adhesive layer ensures the best performance of tight sealing and durability.

Our polyamide- and polyolefin-based hot melts allow for easy processability, durable performance, good flowability during reactivation, and instant bond strength.

Low pressure molding (LPM)

LPM technology serves an important role in protecting and sealing electric component items against moisture, dust and dirt.

Bostik's LPM solutions include Thermelt, a comprehensive range of hot melt polyamide adhesives designed to meet customers’ unique needs. Multipurpose with high temperature resistance and oil, these adhesives offer easy processability at low pressure and low temperatures, enabling them to encapsulate sensitive electronics for the most demanding environments.

Bostik also manufactures reactive polyamides that cure after application to form a cross-linked network providing superior temperature resistance up to 200°C.